In clinical endoscopic applications, ureteroscopes serve as indispensable tools for urological surgery. With advances in endoscopic technology, disposable ureteroscopes and traditional reusable models have emerged as the two predominant choices.

Many wonder why these seemingly functionally similar instruments harbour significant structural and process distinctions. Today, we dissect their differences across three core dimensions: material selection, core component design, and sealing techniques!

The primary requirement for disposable ureteroscopes is low cost and single-use functionality. Consequently, their main frames predominantly utilize medical-grade polymer materials such as PEEK or ABS – lightweight substances that are easily moulded.

Their flexible joints employ micro-injection moulding or single-pass laser cutting, eliminating complex riveted structures. This simplifies production while negating the need for long-term wear resistance, perfectly aligning with a ‘disposable’ application.

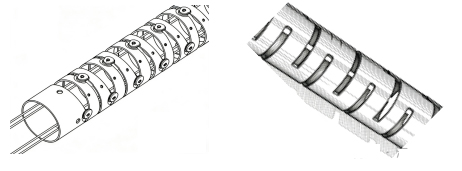

Conversely, reusable ureteroscopes endure dozens or even hundreds of cycles of high-temperature, high-pressure sterilisation and clinical procedures. Material selection prioritises strength and stability. The endoscope housing and core operating components typically employ medical-grade stainless steel or titanium alloys, while the flexible shaft features precision-riveted structures. This design withstands repeated bending and the physical stresses of sterilisation, extending the device's service life.

Sealing performance directly impacts endoscope safety, with each product's design tailored to its specific usage scenario.

Disposable ureteroscopes employ straightforward sealing methods: either single-use injection-moulded sealing rings or ultrasonic welding, sufficient only for leak prevention during a single procedure. Pre-sterilised with ethylene oxide before shipment, they require no consideration for repeated sterilisation compatibility.

Reusable ureteroscopes employ far more complex sealing: a combination of multi-layer medical-grade silicone seals and metal sealing interfaces, with internal waterproof potting compound. This design ensures the device withstands repeated 134°C high-temperature, high-pressure sterilisation cycles without water ingress or component loosening, guaranteeing safety for every procedure.

Differences in handpiece design directly impact clinical usability and post-use maintenance.

The disposable ureteroscope's handle is a monolithic plastic structure, fully integrating the instrument channel, irrigation channel, and scope body with no detachable components. Post-procedure, it requires no cleaning or disinfection—it is simply discarded, offering convenience while eliminating cross-infection risks.

In contrast, the reusable ureteroscope's handle employs a modular design, allowing wear-prone components like knobs and levers to be individually disassembled and replaced. The inner walls of the instrument channel feature a scratch-resistant, wear-resistant coating, facilitating thorough post-operative cleaning to ensure safety and stability for subsequent use.

The manufacturing differences between single-use and reusable ureteroscopes fundamentally reflect a trade-off between application scenarios and cost-effectiveness. Single-use products are better suited for high-infection-risk scenarios and emergency procedures, where maintenance-free operation and cross-infection prevention are core advantages. Reusable products, conversely, align with routine elective surgeries, offering superior long-term cost-effectiveness. However, they necessitate a certain level of maintenance capability within the hospital's endoscopy centre.